|

在當今的汽車產業中,焊接是一個關鍵的環節,采用恰當的焊接方式可以進一步提高車身抗碰撞能力,降低車身重量、造車本錢和油耗以及簡化總裝工序等優勢。目前,汽車采用的焊接一般是點焊,最高級的是“激光焊接”,雖然成本較高,但是物超所值。

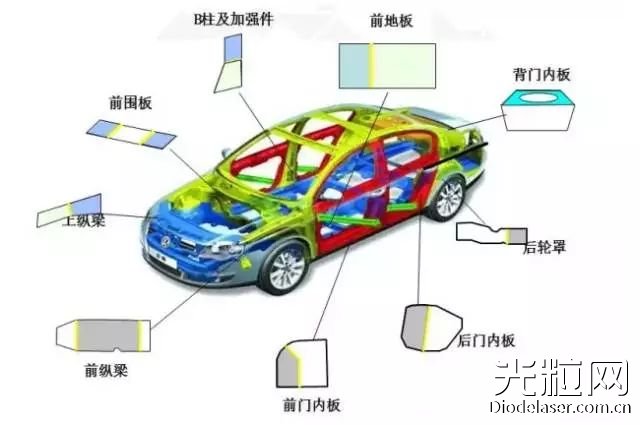

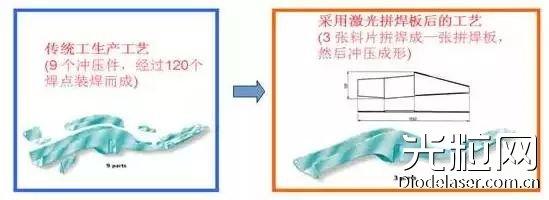

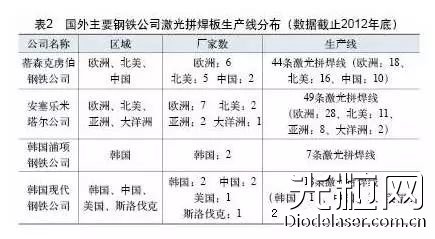

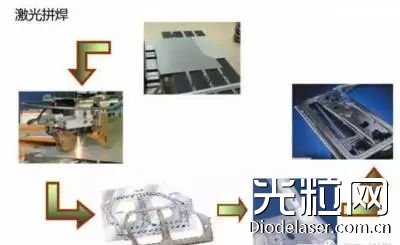

激光焊接是用激光這把“六脈神劍”融化金屬,代替傳統的焊接工藝。在他出現前,焊縫質量不高,汽車製造時隻能使用一整塊鋼板衝壓一個零件,所以以前的汽車又笨重又耗油。 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); text-align: center; letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; overflow-wrap: break-word !important;">而激光焊接出現後,不但焊接質量高,還可以將不同厚度、不同材質甚至不同表麵狀態的鋼板對拚後焊接在一起。焊完後再衝(chong) 壓成所需的零件,這樣設計時可以做到真正的按需選材。所以現代汽車又輕靈又省油。 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; text-align: center; box-sizing: border-box !important; overflow-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">在傳(chuan) 統的白車身製造中,首先需要衝(chong) 壓若幹零件,然後再焊接成分總成,在很多零件上需要焊接加強板類的零件。與(yu) 此相比,拚焊鋼板衝(chong) 壓有很多顯著的優(you) 點,特別是減少工件數量,從(cong) 而減少加工環節、降低生產(chan) 成本。 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; text-align: center; box-sizing: border-box !important; overflow-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); text-align: center; letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">傳(chuan) 統生產(chan) 工藝與(yu) 激光拚焊板工藝的對比 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; overflow-wrap: break-word !important;">相比而言,激光拚焊板優(you) 勢眾(zhong) 多:降低工件重量,從(cong) 而降低整車重量;減少累計公差,利用拚焊板衝(chong) 壓,可以使零件一次衝(chong) 壓成型,不需要將幾個(ge) 零件焊成一個(ge) 零件,大大提高了零件尺寸精度;激光焊接代替傳(chuan) 統電焊,時間可以得到大量節省,焊接質量得到質的提高;提高車身碰撞安全性能等等。 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); text-align: center; letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); text-align: center; letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); text-align: center; letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">拚焊鋼板在車身上的應用 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; overflow-wrap: break-word !important;">目前,中高檔轎車車身已普遍應用激光拚焊板;合資汽車廠轎車車型上的激光拚焊板采用其母公司(或合資夥(huo) 伴)原始車型的設計。但考慮總體(ti) 投資控製,部分拚焊件可能仍為(wei) CKD進口件(如一汽豐(feng) 田的皇冠、一汽-大眾(zhong) 的高爾夫);部分非關(guan) 鍵拚焊件可能更改設計,改為(wei) 等厚板件(如一汽-大眾(zhong) 奧迪A6 L的門檻板)。 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); text-align: center; letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">2002~2009年,我國已建成了32條激光拚焊生產(chan) 線,如下表所示。隨著我國激光拚焊生產(chan) 線的不斷發展,正在逐漸替代進口激光拚焊板。國外先進鋼鐵公司的經驗表明,汽車製造業(ye) 所采用的激光拚焊技術是鋼鐵行業(ye) 延伸產(chan) 業(ye) 鏈的一種行之有效的技術。 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); text-align: center; letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); text-align: center; letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">激光拚焊作為(wei) 一種新的工藝手段,給車身製造帶來新的產(chan) 品解決(jue) 方案,並給質量提高和成本降低帶來了新的機遇。同時由於(yu) 其工藝實施的特殊性,需要產(chan) 品設計、衝(chong) 壓工藝和模具製造等相關(guan) 人員更為(wei) 密切的配合,才能最終製造出既滿足結構和性能要求、工藝合理穩定、成本最低的合格產(chan) 品。 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">1.焊接氣孔問題 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); text-align: center; letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">原因: inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(1)、焊接保護氣體(ti) 不純(解決(jue) 方法:更換純度較高氣體(ti) ) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(2)、焊接保護氣體(ti) 位置不對(解決(jue) 方法:調節銅管吹氣角度和高度位置) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(3)、焊接保護氣體(ti) 流量大小不合適(解決(jue) 方法:調節保護氣體(ti) 流量) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(4)、板材表麵有油汙、水汽或雜質等(解決(jue) 方法:清潔板材焊縫表麵) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">2.焊接斷弧問題 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; text-align: center; box-sizing: border-box !important; overflow-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">原因: inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(1)、焊接參數不合適(解決(jue) 方法:調整焊接功率、速度、焦點、保護氣體(ti) 等參數到合適值) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(2)、外光路鏡片汙染(解決(jue) 方法:檢查並清洗外光路鏡片) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(3)、激光器內(nei) 部鏡片汙染(解決(jue) 方法:檢查並清洗內(nei) 部光路鏡片) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">3. 焊縫表麵有顆粒或者焊縫成型不均勻 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); text-align: center; letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">原因: inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(1)、焊接保護氣體(ti) 不純(解決(jue) 方法:更換純度較高氣體(ti) ) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(2)、焊接保護氣體(ti) 位置不對(解決(jue) 方法:調節銅管吹氣角度和高度位置) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(3)、焊接保護氣體(ti) 流量大小不合適(解決(jue) 方法:調節保護氣體(ti) 流量) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(4)、板材表麵有油汙、水汽或雜質等(解決(jue) 方法:清潔板材焊縫表麵) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">4. 焊縫錯邊問題 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); text-align: center; letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">原因: inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(1)、板材精剪後平整度不一致(解決(jue) 方法:檢查板材平整度) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(2)、焊接平台不平整(解決(jue) 方法:檢查並清理平台是否有焊渣) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">5. 焊縫偏向一側(ce) 板材 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; text-align: center; box-sizing: border-box !important; overflow-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">原因: inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(1)、拚縫時擠壓坐標值過大(解決(jue) 方法:調整合適拚縫擠壓坐標值) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(2)、焊接時激光偏向一側(ce) (解決(jue) 方法:調整焊接時激光到焊縫合適值) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">6. 焊縫局部變窄問題 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; text-align: center; box-sizing: border-box !important; overflow-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">原因: inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(1)、拚縫時間隙值過大(解決(jue) 方法:調整合適拚縫擠壓坐標值或者更換合格板材) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(2)、焊接時激光偏向薄板一側(ce) (解決(jue) 方法:調整焊接時激光到焊縫合適值) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">7.焊縫未焊透 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">原因:焊接時工藝參數不合適(功率過低、速度過快、離焦量過大等) inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">8.焊縫燒穿 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">原因: inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); text-align: center; letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;"> 隨著汽車向著智能化、高端化、多元化的方向發展,汽車輕量化已經大勢所趨;而激光焊接技術作為重要的一個加工技術,將大力推動汽車輕量化製程,成為汽車輕量化路上的得力助手。 結語 (1) 激光焊接技術是用於汽車製造零部件加工的關鍵技術,其中激光拚焊板是最成熟產品。 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(2) 激光拚焊鋼帶技術的高焊接速度和裝卸效率,降低了製造成本,同時也帶來了零部件減重的可能性,這也使生產(chan) 成本得以降低。 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(3) 國外鋼鐵公司,尤其是歐洲地區的鋼鐵公司,具有豐(feng) 富的鋼材深加工生產(chan) 經驗,可根據下遊汽車廠用戶的需求生產(chan) 出滿足汽車設計和製造要求的產(chan) 品。 inkMacSystemFont, Arial, sans-serif; color: rgb(62, 62, 62); letter-spacing: 0.5px; box-sizing: border-box !important; word-wrap: break-word !important;">(4) 隨著新興(xing) 汽車市場,尤其是中國汽車工業(ye) 的發展,國外鋼鐵公司與(yu) 國內(nei) 大型鋼企合資建設激光拚焊板生產(chan) 線。此外,汽車板生產(chan) 企業(ye) 也采取與(yu) 汽車廠、擁有激光拚焊技術的鋼鐵企業(ye) 合資興(xing) 建的方式,逐步開拓市場穩定用戶、提高工藝技術水平。 |

轉載請注明出處。

相關文章

相關文章

熱門資訊

熱門資訊

精彩導讀

精彩導讀

關注我們

關注我們