seline;color:#666666;font-size:16px;font-weight:normal;"> 你是否知道

seline;color:#666666;font-size:16px;font-weight:normal;"> 激光束的入射方向及入射角度會(hui) 直接影響焊縫熔池的形狀及其流動形態,這會(hui) 對焊縫成型與(yu) 性能產(chan) 生重要影響。

seline;color:#666666;font-size:16px;font-weight:normal;"> 為(wei) 了了解激光束與(yu) 焊縫的相對位置對焊縫的影響,我們(men) 做了兩(liang) 次實驗,分別用非高反材料和高反材料進行測試。

seline;color:#666666;font-size:16px;font-weight:normal;"> 本期【Rayclass | 銳課堂】首先來看看高功率多模組連續激光器RFL-C4000(纖芯100μm)在焊接非高反材料(不鏽鋼為(wei) 例)時受激光束入射相對位置對焊縫的影響規律。

seline;color:#666666;font-size:16px;font-weight:normal;"> 1)

seline;color:#666666;font-size:16px;font-weight:normal;"> 試驗材料

seline;color:#666666;font-size:16px;font-weight:normal;"> Experiment Material

seline;color:#666666;font-size:16px;font-weight:normal;"> 6mm厚的304不鏽鋼

seline;color:#666666;font-size:16px;font-weight:normal;"> 6mm thick 304 stainless steel

seline;color:#666666;font-size:16px;font-weight:normal;"> 2)

seline;color:#666666;font-size:16px;font-weight:normal;"> 試驗設備

seline;color:#666666;font-size:16px;font-weight:normal;"> Experiment Equipment

seline;color:#666666;font-size:16px;font-weight:normal;"> 4000W多模組連續光纖激光器(配備100μm芯徑的光纖)、懸臂式焊接工作台、焊接頭(準直鏡焦長100mm,聚焦鏡焦長300mm)

seline;color:#666666;font-size:16px;font-weight:normal;"> 4000W multi-module CW fiber laser (with 100μm core fiber), cantilever welding table, welding head (100mm collimator lens focal length, 300mm focusing lens length)

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;"> 3)

seline;color:#666666;font-size:16px;font-weight:normal;"> 試驗方法

seline;color:#666666;font-size:16px;font-weight:normal;"> Experiment Method

seline;color:#666666;font-size:16px;font-weight:normal;"> 首先用300W高功率脈衝(chong) 光纖激光器,將待焊材料表麵的氧化層及油汙去除;

seline;color:#666666;font-size:16px;font-weight:normal;"> Firstly, the oxide layer and oil stain on the surface of the material to be welded are removed by using a 300W high power pulsed fiber laser.

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;"> 隨後,將兩(liang) 種材料進行堆焊。

seline;color:#666666;font-size:16px;font-weight:normal;"> then, the two materials were bead welding.

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;"> 4)

seline;color:#666666;font-size:16px;font-weight:normal;"> 試驗過程

seline;color:#666666;font-size:16px;font-weight:normal;"> Experimental Procedure

seline;color:#666666;font-size:16px;font-weight:normal;"> 按照設定好的參數進行焊接試驗,試驗參數如下表所示,試驗完成後對試板進行線切割取樣,然後進行金相製取並檢測分析。

seline;color:#666666;font-size:16px;font-weight:normal;"> The welding test is carried out according to the set parameters. The test parameters are shown in the following table. After the test is completed, the test plate is subjected to wire cutting sampling, and then the metallographic preparation is carried out and tested.

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;"> 表1中所謂的光束入射方向表述是相對於(yu) 焊接方向進行確定的,如圖1所示,

seline;color:#666666;font-size:16px;font-weight:normal;"> The so-called beam incidence direction expression is determined relative to the welding direction.

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;" class="ql-align-center"> 圖1 激光束入射方向

seline;color:#666666;font-size:16px;font-weight:normal;"> Graph 1. Laser beam incident direction

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;"> 光束入射角度表述為(wei) 激光束與(yu) 試板法線的夾角,如圖2所示。

seline;color:#666666;font-size:16px;font-weight:normal;"> As shown in Graph 2, the angle of incidence of the beam is expressed as the angle between the laser beam and the normal of the test plate.

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;"> 5)

seline;color:#666666;font-size:16px;font-weight:normal;"> 試驗結果

seline;color:#666666;font-size:16px;font-weight:normal;"> Experiment Result

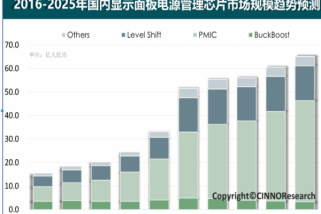

seline;color:#666666;font-size:16px;font-weight:normal;"> 不鏽鋼304的焊接試驗檢測結果如下表所示。

seline;color:#666666;font-size:16px;font-weight:normal;"> The welding test results of 304 stainless steel are shown in the following table.

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;"> (圖中橫坐標數值表示光束入射角度值,“負值”表示光束前傾(qing) ,“正值”表示光束後傾(qing) )

seline;color:#666666;font-size:16px;font-weight:normal;"> Graph 3 Effect of beam position on penetration and melting width when welding aluminum alloy

seline;color:#666666;font-size:16px;font-weight:normal;"> (the abscissa value indicates the incident angle of the beam, the negative value indicates the forward tilt of the beam, and the positive value indicates the backward tilt of the beam.)

seline;color:#666666;font-size:16px;font-weight:normal;"> 從(cong) 表2和圖3可以看出,激光垂直入射焊接時的焊縫熔深最大,光束入射角度越大,熔深越淺,並且在同一入射角度時光束前傾(qing) 相對於(yu) 光束後傾(qing) 的熔深略小。

seline;color:#666666;font-size:16px;font-weight:normal;"> It can be seen from Table 2 and Graph 3 that the weld penetration is maximum when laser perpendicular incidence welding. Meanwhile, the larger the incident angle of the beam, the shallower the penetration, and at the same angle of incidence, the depth of fusion of beam forward is slightly smaller than beam backward.

seline;color:#666666;font-size:16px;font-weight:normal;"> 有學者郭鴻鵬對此進行了深入研究,其主要結論可闡述為(wei) :主要是因為(wei) 光束射入焊縫形成小孔效應時,因液態金屬受向外噴發的金屬蒸汽羽的反作用力而流動:當光束垂直入射時,該反作用力幾乎是垂直向下將液態金屬推向熔池底部;當光束前傾(qing) 時,該反作用力方向趨於(yu) 水平,並且當傾(qing) 角越大時,該反作用力方向越趨於(yu) 水平,如圖4(a)所示,使熔池頭部的液態金屬流向熔池尾部,熔池底部的液態金屬因為(wei) 摩擦力的作用而向上流動;當光束後傾(qing) 時,該反作用力方向是垂直於(yu) 小孔前壁斜向下,如圖4(b)所示,所以有垂直向下的分力作用於(yu) 熔池頂部的液態金屬,使其向下流向熔池底部,同時當傾(qing) 角越大時,小孔前壁越陡峭,該反作用力方向越趨於(yu) 水平,其垂直向下的分力就會(hui) 越小。

seline;color:#666666;font-size:16px;font-weight:normal;"> Some scholars have studied the phenomenon of this result that when the beam is injected into the weld to form a small hole effect, the liquid metal flows due to the reaction force of the outwardly ejected metal vapor plume. When the beam is incident vertically, the reaction force pushes the liquid metal toward the bottom of the molten pool almost vertically downwards. When the beam is tilted forward, the direction of the reaction force tends to be horizontal, and when the angle of inclination is larger, the direction of the reaction force tends to be horizontal. As shown in Graph 4(a), the liquid metal at the head of the molten pool flows toward the tail of the molten pool, and the liquid metal at the bottom of the molten pool flows upward due to the frictional force. However, when the beam is tilted backward, the direction of the reaction force is perpendicular to the front wall of the small hole. As shown in Graph 4(b), there is a vertical downward component acting on the liquid metal at the top of the molten pool, causing it to flow down to the bottom of the pool. At the same time, the larger the inclination angle, the steeper the front wall of the small hole, the more the direction of the reaction force tends to be horizontal, and the smaller the vertical downward force component will be.

seline;color:#666666;font-size:16px;font-weight:normal;"> 熔池中的液態金屬均是高溫狀態,具有較大的熱量,進入熔池底部的液態金屬越多,就會(hui) 帶入越多的熱量至熔池底部,從(cong) 而使其能夠更多的通過熱傳(chuan) 導方式熔化更多的熔池底部邊緣的母材金屬,進而增大焊縫熔深。液態金屬受到的向熔池底部方向的力越大,就會(hui) 有越多的液態金屬流入熔池底部,就會(hui) 產(chan) 生更大的熔深,所以就會(hui) 出現上述圖3中熔深曲線所表明的現象。

seline;color:#666666;font-size:16px;font-weight:normal;"> The liquid metal in the molten pool is at a high temperature and has a large amount of heat. The more liquid metal that enters the bottom of the pool, the more heat it carries into the bottom of the molten pool. Therefore, it can more melt the base metal of the bottom edge of the molten pool by heat conduction, thereby increasing the weld penetration. The greater the force that the liquid metal receives in the direction toward the bottom of the molten pool, the more liquid metal will flow into the bottom of the pool. It will produce a larger penetration, so the phenomenon indicated by the penetration curve in Graph 3 above will occur.

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;">

seline;color:#666666;font-size:16px;font-weight:normal;" class="ql-align-center"> 圖4 液態金屬在不同光束位置時的受力狀態

seline;color:#666666;font-size:16px;font-weight:normal;"> Graph 4. Force state of liquid metal at different beam positions

seline;color:#666666;font-size:16px;font-weight:normal;"> 從(cong) 表2中不鏽鋼焊縫橫截麵金相和焊縫表麵成型來看,光束傾(qing) 角大小及方向對焊縫氣孔的產(chan) 生幾乎沒有影響,均可得到無氣孔的焊縫,但是光束傾(qing) 角大的時候焊縫成型均勻性會(hui) 相對差一些,這可能是因為(wei) 光束傾(qing) 角較大時,焊縫熔池金屬的流動狀態發生了較大改變,容易出現不穩定的狀態。

seline;color:#666666;font-size:16px;font-weight:normal;"> From the perspective of the metallographic and weld surface of the stainless-steel weld cross section in Table 2, the size and direction of the beam inclination have hardly any effect on the generation of weld porosity, and a weld without voids can be obtained. But the uniformity of weld formation will be relatively poor when the beam angle is large. This may be because when the beam inclination angle is large, the flow state of the weld pool metal changes greatly, and it is prone to unstable state.

seline;color:#666666;font-size:16px;font-weight:normal;"> 6)

seline;color:#666666;font-size:16px;font-weight:normal;"> 結論

seline;color:#666666;font-size:16px;font-weight:normal;"> Conclusion

seline;color:#666666;font-size:16px;font-weight:normal;"> I)不鏽鋼激光自熔焊時,激光束垂直入射的焊縫熔深最大,光束入射角度越大,熔深越淺,並且在同一入射角度時光束前傾(qing) 相對於(yu) 光束後傾(qing) 的熔深略小;

seline;color:#666666;font-size:16px;font-weight:normal;"> When single laser welding stainless steel, the depth of weld joint is the greatest when laser beam is incident vertically. Meanwhile, the larger the beam incidence angle, the shallower the fusion depth. And at the same incident angle, the fusion depth of the forward dip is slightly smaller than the backward dip of the beam.

seline;color:#666666;font-size:16px;font-weight:normal;"> II)不鏽鋼激光自熔焊時,激光束入射傾(qing) 角大小及方向對焊縫氣孔的產(chan) 生幾乎沒有影響,均可得到無氣孔的焊縫,但是光束傾(qing) 角大時焊縫成型均勻性會(hui) 相對差一些。

seline;color:#666666;font-size:16px;font-weight:normal;"> When single laser welding stainless steel, the angle and direction of the incident angle of the laser beam have almost no effect on the generation of weld porosity, and a weld without voids can be obtained. However, the uniformity of weld formation will be relatively poor when the beam angle is large.

seline;color:#666666;font-size:16px;font-weight:normal;"> 看完了4000W連續光纖激光器(纖芯100μm)在焊接非高反材料時受激光束入射相對位置對焊縫的影響規律測試後,您是否也想知道,對於(yu) 高反材料這種結論是否也同樣適用?

轉載請注明出處。

相關文章

相關文章

熱門資訊

熱門資訊

精彩導讀

精彩導讀

關注我們

關注我們